Research Situation Analysis of Global Transportation Aluminum Alloy Technology Based on CiteSpace Knowledge Map

-

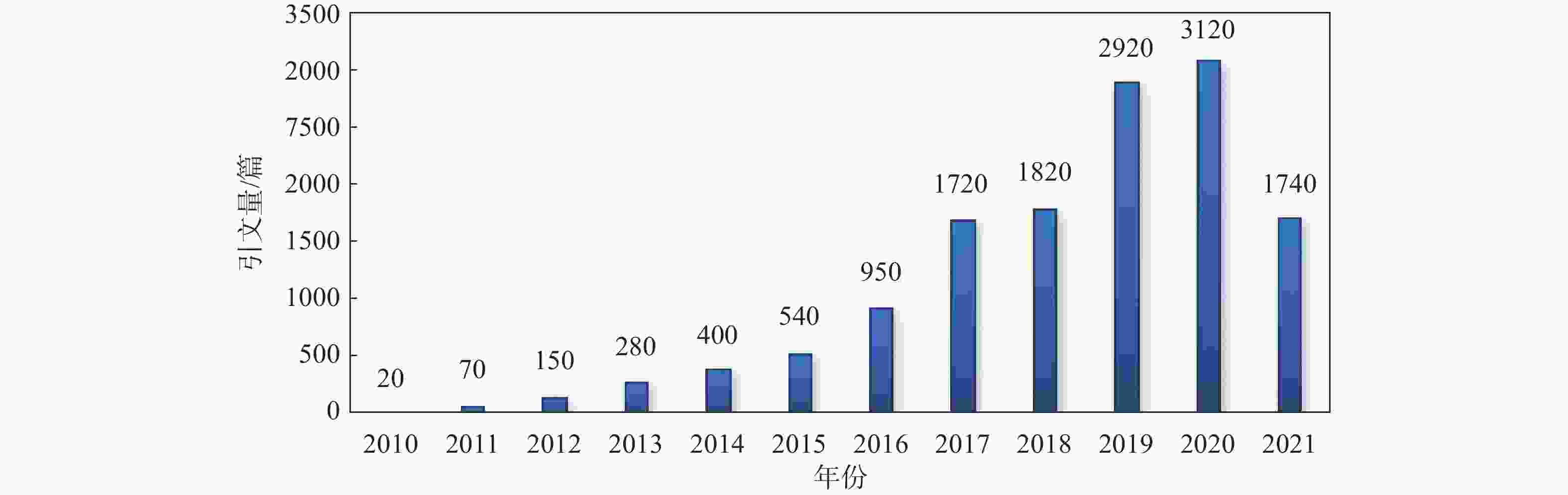

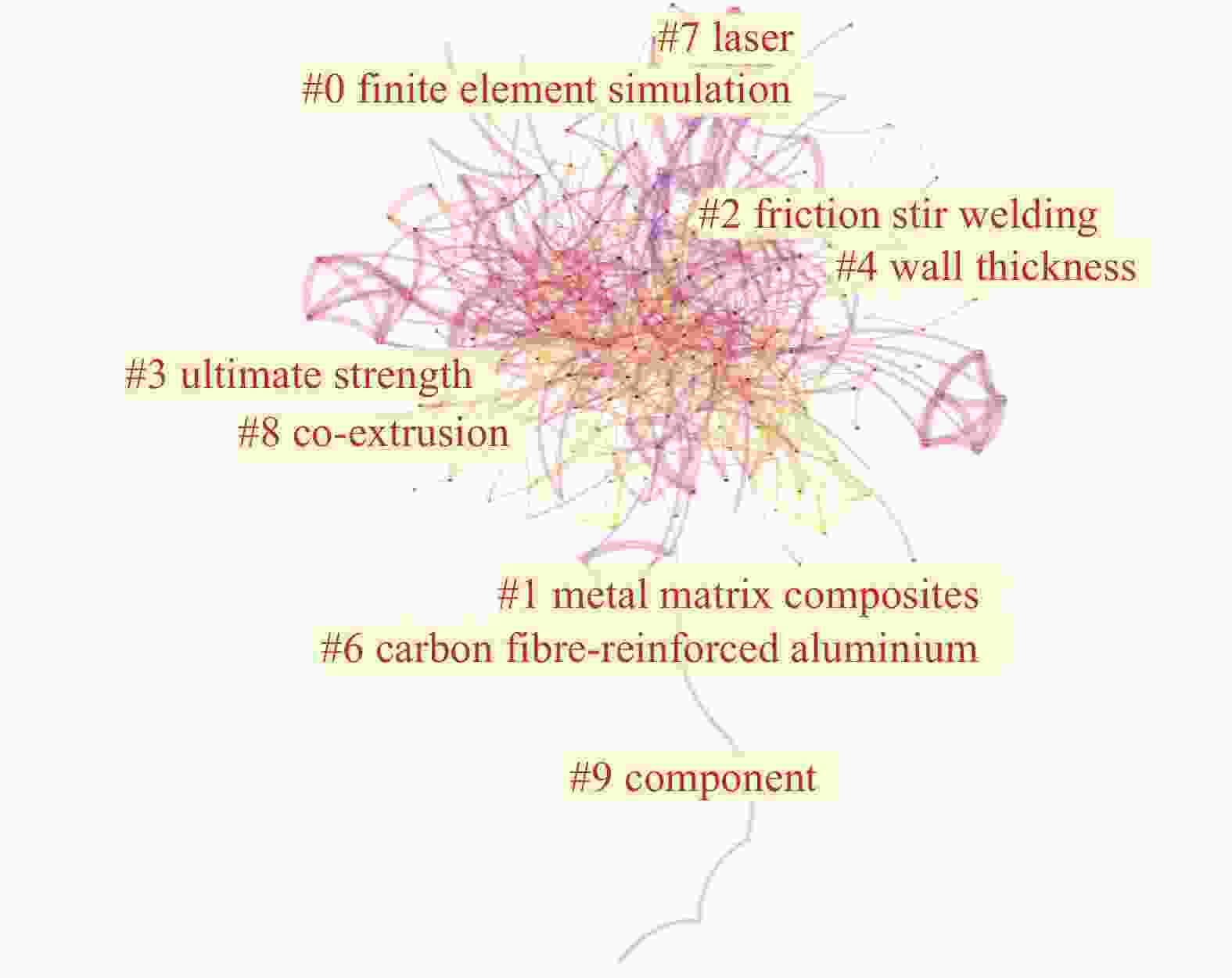

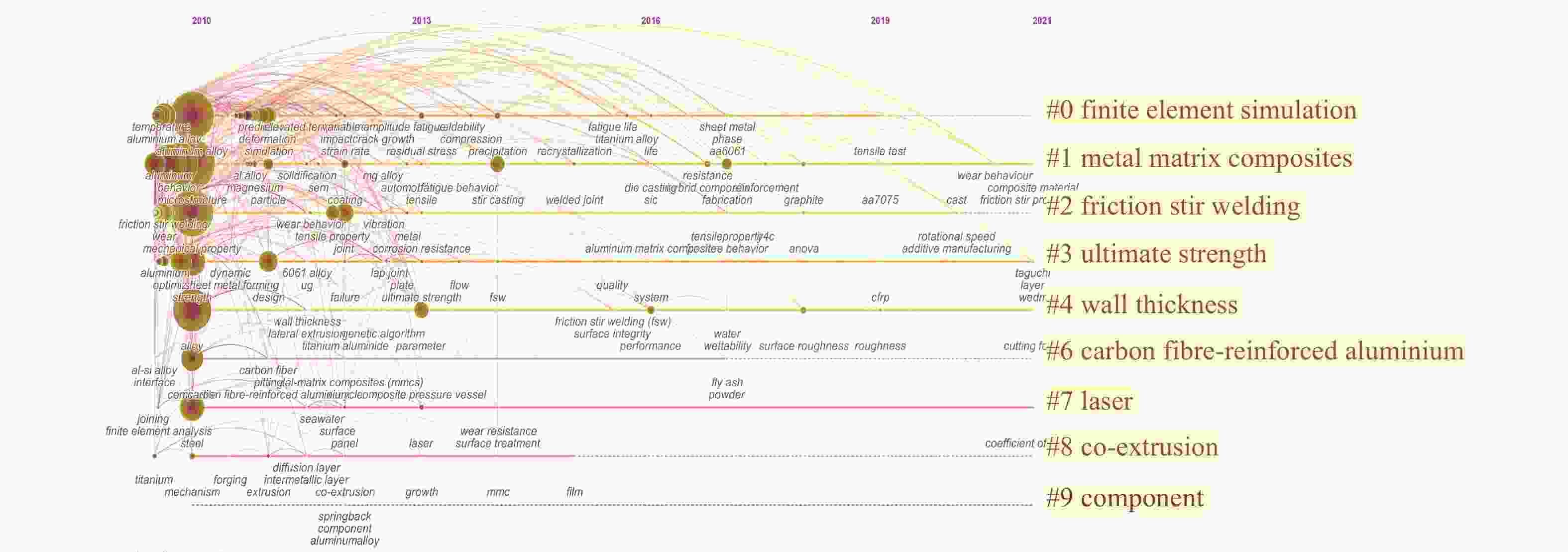

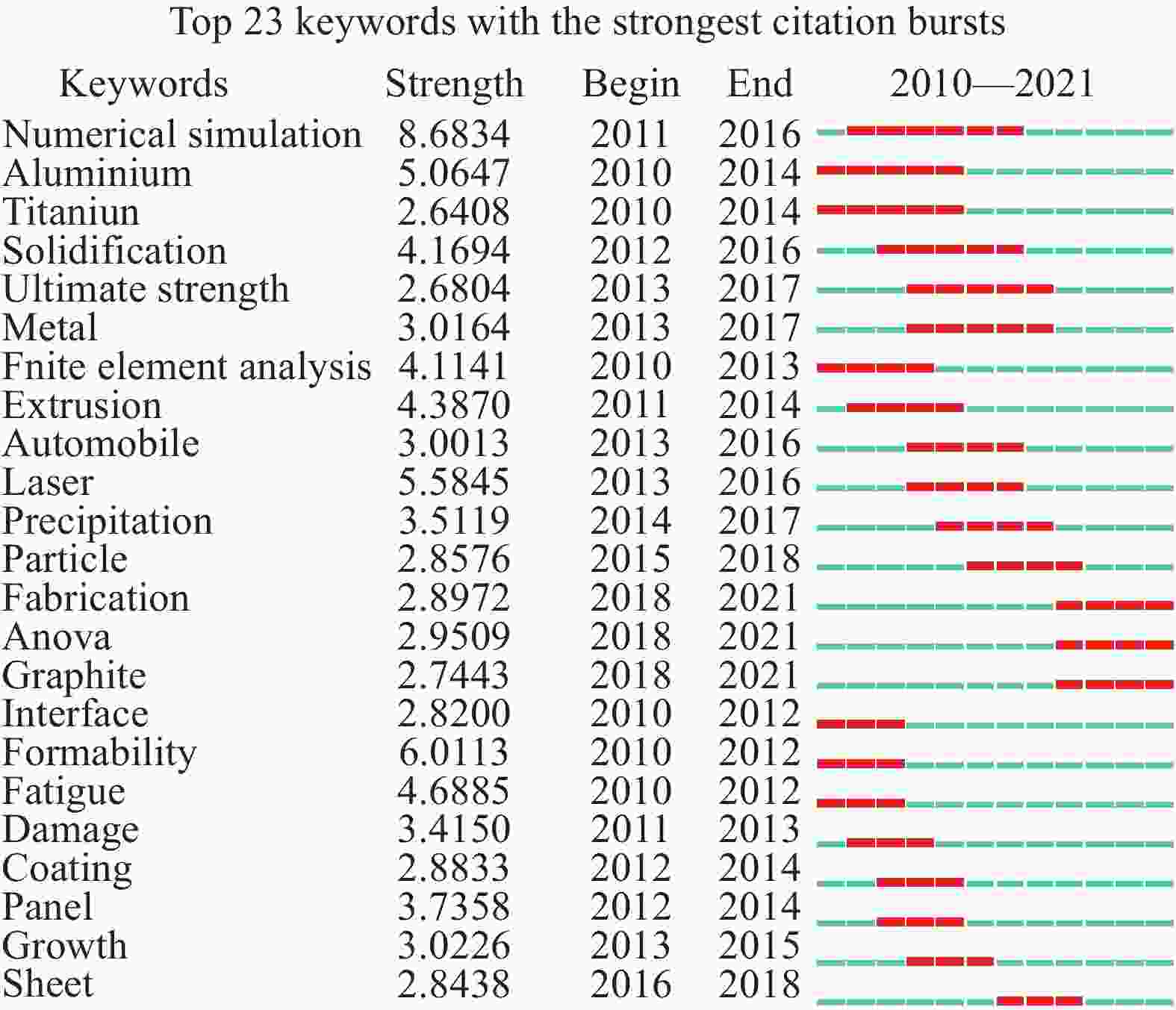

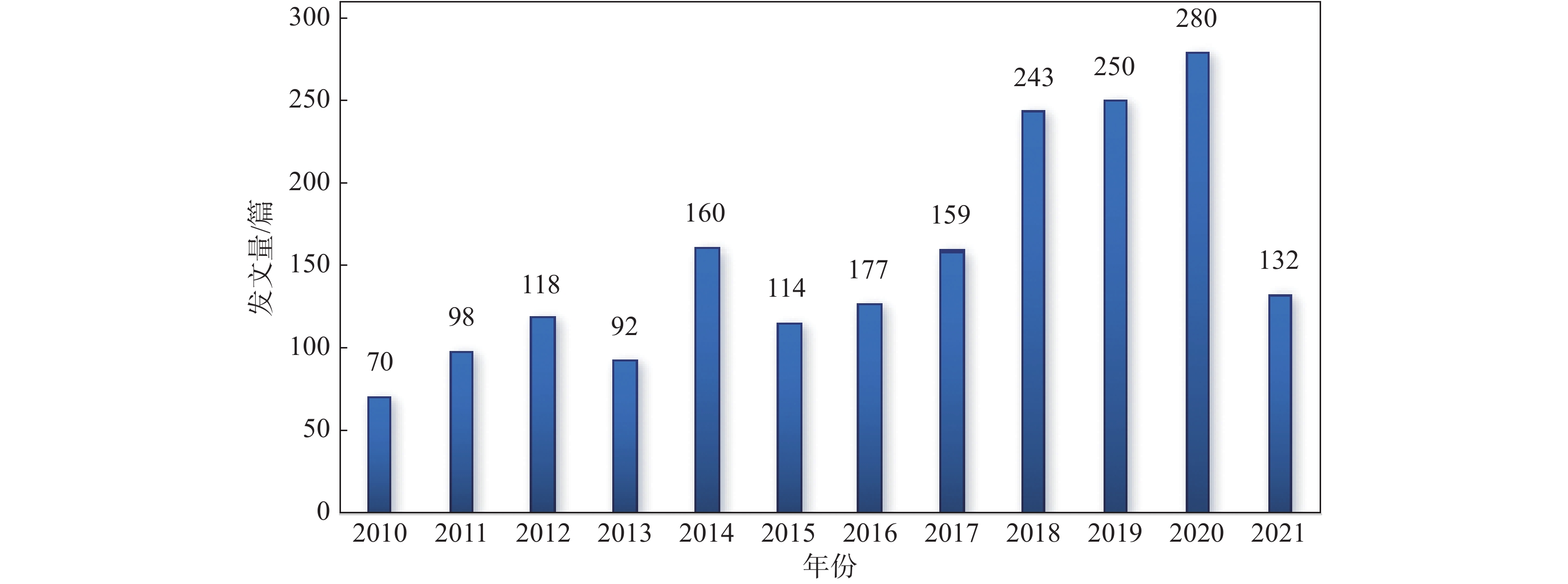

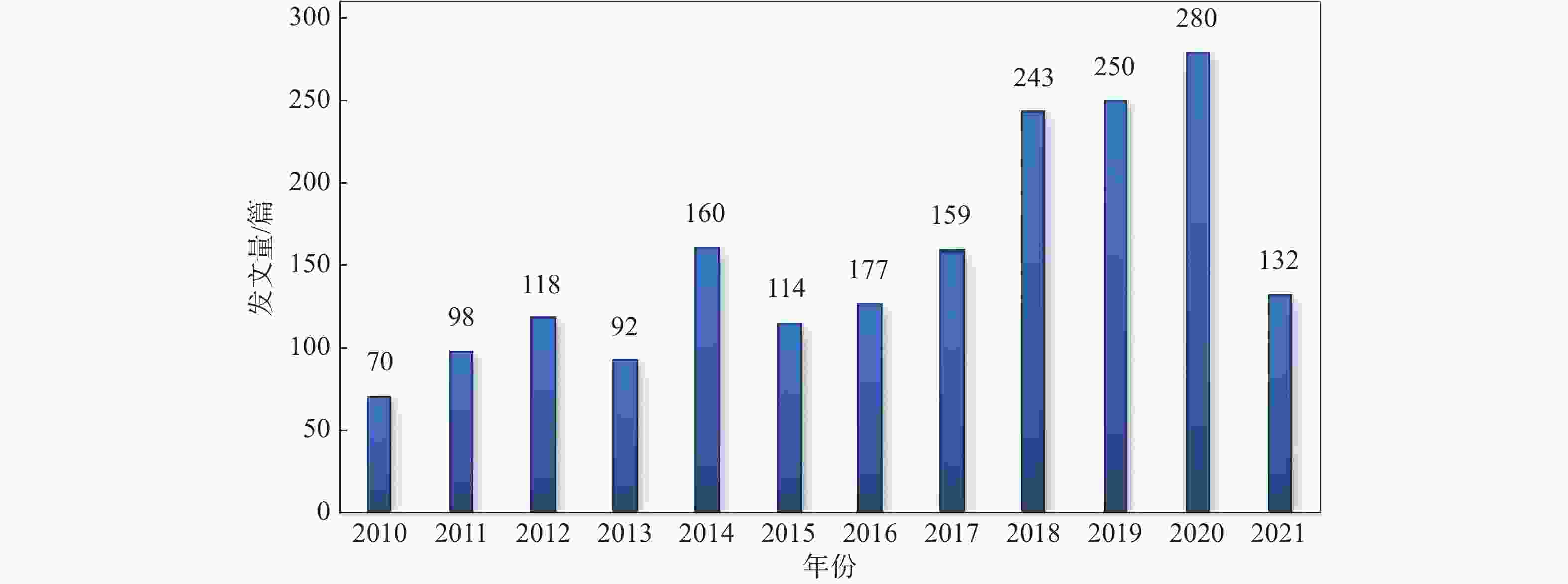

摘要: 交通运输设备轻量化趋势愈加明朗,而铝合金因其多种优良特性已成为实现轻量化交通的重要材料。本文通过文献计量学方法,着重分析全球交通用铝合金领域发文量、机构、国家及关键词等信息,绘制形成可视化网络图谱。结果显示:研究主要集中在汽车和航空领域,包括铝基复合材料和焊接技术;船舶用铝合金的研究重点为铝合金表面涂层;而轨道交通用铝合金的研究数量相对较少,且与汽车、航空领域的文献有较多交叉,表明其部分技术与汽车、航空用铝合金具有通用性。

-

表 1 交通用铝合金技术领域发文量排名前十的国家

序号 国家 发文量/篇 占比/% 1 印度(INDIA) 487 26.31 2 中国(PEOPLES R CHINA) 459 24.80 3 美国(USA) 130 7.02 4 韩国(SOUTH KOREA) 128 6.91 5 日本(JAPAN) 75 4.05 6 德国(GERMANY) 71 3.84 7 波兰(POLAND) 64 3.46 8 俄罗斯(RUSSIA) 61 3.30 9 土耳其(TURKEY) 58 3.13 10 英格兰(ENGLAND) 46 2.49 表 2 交通用铝合金技术领域发文量排名前十的研究机构

序号 研究机构 发文量/篇 占比/% 1 哈尔滨工业大学(HARBIN INST TECHNOL) 36 1.93 2 印度国立理工学院(NATL INST TECHNOL) 30 1.61 3 中国科学院(CHINESE ACAD SCI) 28 1.51 4 安娜大学(ANNA UNIV) 21 1.13 5 印度理工学院(INDIAN INST TECHNOL) 19 1.02 6 西北工业大学(NORTHWESTERN POLYTECH UNIV) 19 1.02 7 西南交通大学(SOUTHWEST JIAOTONG UNIV) 18 0.97 8 中南大学(CENT S UNIV) 17 0.91 9 北京科技大学(UNIV SCI TECHNOL BEIJING) 16 0.86 10 印度韦洛尔理工大学(VIT UNIV) 15 0.81 表 3 技术主题研究热点统计

序号 频率 中心度 技术热点关键词 中文含义 1 73 0.15 Metal matrix Composite 金属基复合材料 2 319 0.07 Mechanical property 机械性能 3 78 0.07 Friction stir welding 搅拌摩擦焊接 4 75 0.06 Optimization 优化 5 24 0.06 Tensile strength 抗拉强度 6 2 0.06 Springback 回弹 7 360 0.05 Microstructure 微观结构 8 26 0.03 Numerical simulation 数值模拟 9 12 0.03 Finite element analysis 有限元分析 10 9 0.03 Extrusion 挤压 11 70 0.02 Corrosion 腐蚀 12 46 0.02 Stir casting 搅拌铸造 13 42 0.02 Tensile property 拉伸性能 14 40 0.02 Friction 摩擦 15 32 0.02 Heat treatment 热处理 16 21 0.02 Coating 图层 17 18 0.02 Formability 成形性 18 17 0.02 Resistance 电阻 19 16 0.02 Powder metallurgy 粉末冶金 20 15 0.02 Graphite 石墨 21 3 0.02 Surface treatment 表面处理 22 21 0.01 Surface roughness 表面粗糙度 23 18 0.01 Matrix composite 基体复合材料 -

[1] 李烨. 浅谈我国交通运输经济现状与未来发展方向. 绿色环保建材, 2019(9):254 [2] 聂德键,罗铭强,陈文泗,等. 交通运输用铝合金材料研究进展. 有色金属加工, 2016,45(5):15 [3] 梁国强. 国内文献计量学综述. 科技文献信息管理, 2013,27(4):58 [4] 陈悦,陈超美,刘则渊,等. CiteSpace知识图谱的方法论功能. 科学学研究, 2015,33(2):242 [5] 天风期货. 印度第二波疫情浪潮来袭,对铝工业有何影响?(2021–05–06)[2022–07–01]. http://db.cnmn.com.cn/NewsShow.aspx?id=427590 [6] 李杰,陈美超. CiteSpace:科技文本挖掘及可视化. 2版. 北京:首都经济贸易大学出版社,2017 [7] 李家奇,杨钢,陈俊宇,等. 汽车轻量化铝合金研究进展. 云南冶金, 2020,49(5):68 [8] Mohanavel V, Rajan K, Arul S. Production, microstructure and mechanical behavior of AA6351/TiB2 composite synthesized by direct melt reaction method. Mater Today Proc, 2017, 4(2): 3315 doi: 10.1016/j.matpr.2017.02.218 [9] Reddy A P, Krishna P V, Rao R N, et al. Silicon carbide reinforced aluminium metal matrix nano composites: A review. Mater Today Proc, 2017, 4(2): 3595 [10] Jagannatham M, Prathap C, Bakshi S, et al. Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon, 2020: 16014 [11] Gupta P K, Srivastava R K. Fabrication of ceramic reinforcement aluminium and its alloys metal matrix composite materials: A review. Mater Today Proc, 2018, 5(9): 18761 doi: 10.1016/j.matpr.2018.06.223 [12] Sarada B N, Murthy P L S, Ugrasen G. Hardness and wear characteristics of hybrid aluminium metal matrix composites produced by stir casting technique. Mater Today Proc, 2015, 2(4/5): 2878 [13] Mohanavel V, Rajan K, Kumar S S, et al. Study on mechanical properties of graphite particulates reinforced aluminium matrix composite fabricated by stir casting technique. Mater Today Proc, 2018, 5(1): 2945 doi: 10.1016/j.matpr.2018.01.090 [14] Prangnell P, Haddadi F, Chen Y C. Ultrasonic spot welding of aluminium to steel for automotive applications-microstructure and optimisation. Mater Sci Technol, 2011, 27(3): 617 doi: 10.1179/026708310X520484 [15] Dwivedi S P. Effect of process parameters on tensile strength of friction stir welding A356/C355 aluminium alloys joint. J Mech Sci Technol, 2014, 28(1): 285 doi: 10.1007/s12206-013-0967-0 [16] Kayode O, Akinlabi E T. An overview on joining of aluminium and magnesium alloys using friction stir welding (FSW) for automotive lightweight applications. Mater Res Express, 2019, 6(11): 2005 [17] Ogawa Y, Akebono H, Tanaka K, et al. Effect of welding time on fatigue properties of friction stir spot welds of al to carbon fibre-reinforced plastic. Sci Technol Weld Joining, 2019, 24(3): 235 doi: 10.1080/13621718.2018.1535781 [18] Kumar A, Khurana M K, Singh G. Modeling and optimization of friction stir welding process parameters for dissimilar aluminium alloys. Mater Today Proc, 2018, 5(11): 25440 doi: 10.1016/j.matpr.2018.10.349 [19] 张新明,刘胜胆. 航空铝合金及其材料加工. 中国材料进展, 2013,32(1):39 [20] 刘牧东. 航空铝合金材料低温裂纹扩展研究现状与展望. 航空工程进展, 2020,11(1):10 [21] Rioja R J, Liu J. The evolution of Al–Li base products for aerospace and space applications. Metall Mater Trans A, 2012, 43(9): 3325 doi: 10.1007/s11661-012-1155-z [22] Imran M, Khan A R A. Characterization of Al-7075 metal matrix composites: a review. J Mater Res Technol, 2019, 8(3): 3347 doi: 10.1016/j.jmrt.2017.10.012 [23] Li P T, Li Y G, Wu Y Y, et al. Distribution of TiB2 particles and its effect on the mechanical properties of A390 alloy. Mat Sci Eng A, 2012, 546: 146 doi: 10.1016/j.msea.2012.03.042 [24] Vinayagam M. Synthesis and evaluation on mechanical properties of LM4/AlN alloy based composites. Energ Source Part A, 2022, 44(1): 1888 doi: 10.1080/15567036.2019.1647313 [25] Bommana D, Dora T R K, Senapati N P, et al. Effect of 6wt% particle(B4C+SiC) reinforcement on mechanical properties of AA6061 aluminum hybrid MMC. Silicon, 2022, 14(8): 4197 [26] Fu R D, Sun Z Q, Sun R C. et al Improvement of weld temperature distribution and mechanical properties of 7050 aluminum alloy butt joints by submerged friction stir welding. Mater Design, 2011, 32(10): 4825 doi: 10.1016/j.matdes.2011.06.021 [27] SanoY, Masaki K, Gushi T, et al. Improvement in fatigue performance of friction stir welded A6061-T6 aluminum alloy by laser peening without coating. Mater Design, 2012, 36: 809 doi: 10.1016/j.matdes.2011.10.053 [28] Fu B L, Qin G L, Meng X M, et al. Microstructure and mechanical properties of newly developed aluminum-lithium alloy 2A97 welded by fiber laser. Mat Sci Eng A, 2014, 617: 1 doi: 10.1016/j.msea.2014.08.038 [29] Yang Z B, Tao W, Li L Q, et al. Double-sided laser beam welded t-joints for aluminum aircraft fuselage panels: process, microstructure, and mechanical properties. Mater Design, 2012, 33: 652 doi: 10.1016/j.matdes.2011.07.059 [30] Verma S, Gupta M, Misra J P. Study of thermal cycle, mechanical, and metallurgical properties of friction stir welded aviation grade aluminum alloy. Proc Inst Mech Eng Part G, 2019, 233(11): 4202 doi: 10.1177/0954410018816601 [31] 罗彦云,蒲全卫,左国良. 铝合金和镁合金在轨道交通装备轻量化上的应用. 电力机车与城轨车辆, 2020,43(3):1 doi: 10.16212/j.cnki.1672-1187.2020.03.001 [32] Sheng X F, Li K, Wu W K, et al. Microstructure and mechanical properties of friction stir welded joint of an aluminum alloy sheet 6005A-T4. Metals, 2019, 9(11): 1152 doi: 10.3390/met9111152 [33] Daneji A, Ali M, Pervaiz S. Influence of tool geometry and processing parameters on welding defects and mechanical properties for friction stir welding of 6061 aluminium alloy. IOP Conf Ser Mater Sci Eng, 2018, 346: Art No. 012041 [34] Barbieri G, Cognini F, Lapi G, et al. Mechanical behavior of aluminum sandwiches made by laser welding. Procedia Eng, 2015, 109: 427 doi: 10.1016/j.proeng.2015.06.256 [35] Singla Y K, Chhibber R, Bansal H, et al. Wear behavior of aluminum alloy 6061-based composites reinforced with SiC, Al2O3, and red mud: a comparative study. JOM, 2015, 67(9): 2160 doi: 10.1007/s11837-015-1365-0 [36] Sohag M A Z, Gupta P, Kondal N, et al. Effect of ceramic reinforcement on the microstructural, mechanical and tribological behavior of Al–Cu alloy metal matrix composite. Mater Today Proc, 2020, 21: 1407 doi: 10.1016/j.matpr.2019.08.179 [37] Kim S J, Jang S K, Han M S, et al. Mechanical and electrochemical characteristics in sea water of 5052-O aluminum alloy for ship. Trans Nonferrous Met Soc China, 2013, 23(3): 636 doi: 10.1016/S1003-6326(13)62510-8 [38] Pathak S S, Mendon S K, Blanton M D, et al. Magnesium-based sacrificial anode cathodic protection coatings (Mg-Rich Primers) for aluminum alloys. Metals, 2012, 2(3): 353 doi: 10.3390/met2030353 [39] Fahim J, Hadavi S M M, Ghayour H, et al. Cavitation erosion behavior of super-hydrophobic coatings on Al5083 marine aluminum alloy. Wear, 2019, 424: 122 [40] Lee S J, Han M S, Kim S J. Evaluation of corrosion resistance for two-step aluminum anodizing with processing time. J Nanosci Nanotechnol, 2016, 16(11): 11262 doi: 10.1166/jnn.2016.13490 [41] Lee L D, Kim S J. Influence of thermally sprayed WC–Co‒Cr coatings on the corrosion characteristics of Ni‒Al bronze alloy. Int J Electrochem Sci, 2021, 16(7): 1 [42] EgorkinV S, Vyalyi I E, Gnedenkov S V. Corrosion properties of Amg3 aluminum alloy treated by short-Pulse plasma electrolytic oxidation in marine conditions. Mar Intellect Techno, 2021(4): 117 -

下载:

下载: